WELCOME TO GARNEAU

MANUFACTURING INC.

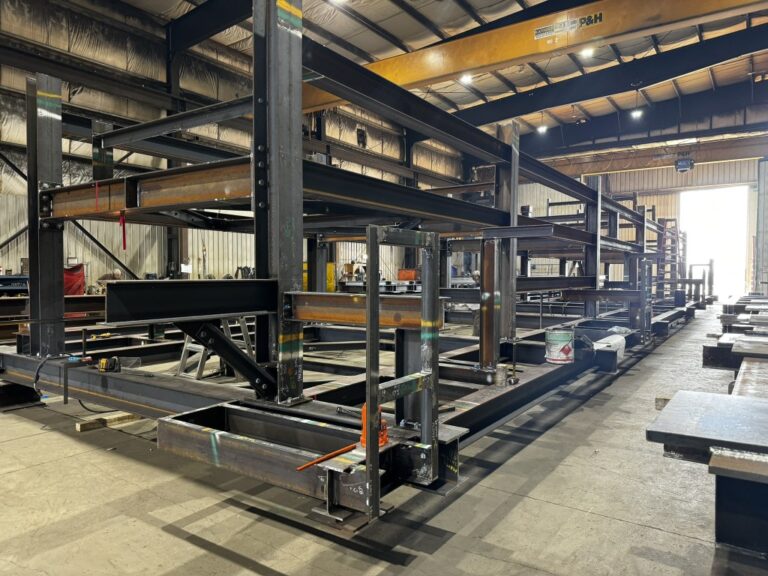

MODULAR FABRICATION

Garneau Manufacturing specializes in the fabrication and assembly of steel modules destined for the oil and gas industry.

CUSTOM & STRUCTURAL STEEL FABRICATION

With quality products to exacting requirements, our staff are experts in manufacturing steel products for unique and specialty applications.

DRAFTING, ESTIMATING, ENGINEERING & DESIGN

Garneau overseas a team of experienced professionals with design expertise in various aspects of structural steel fabrication and erection.

Garneau Manufacturing is an integrated upstream and midstream fabrication services provider to the energy and resource industry, covering the extent of the product life-cycle and all spectrums of its clients’ projects.

About Garneau Manufacturing Inc.

Located in Morinville, Alberta, Garneau Manufacturing offers structural metal fabrication services to a broad range of industries. With over 40 years of experience, our knowledgeable staff are uniquely qualified to take your project from design to finished product, providing turnkey fabrication services.

Our expertise in structural fabrication services provides us with the ability to understand your application and work with you to recommend the most effective fabrication and finishing services to ensure that the product we manufacture will meet all your application requirements. We’ll provide the solution so that your project is done right, on time and on budget.

We serve all industries, specializing in the oil and gas, power generation, offshore construction, railroad, petrochemical, mining and process equipment industries.

What's New at Our Morinville Shop!

We now have CNC Equipment Services!

Garneau Manufacturing has a dedicated team of CNC Equipment operators who can cut and drill plate, angle iron, steel beams, pipe.. Practically, anything upon request and to specifications. Whether it be for a larger module or steel for an individual job, Garneau’s CNC equipment is ready to serve. We have three pieces of equipment:

Garneau Manufacturing operates from a modern 37,500 square foot fabrication facility within a 6 acre laydown module yard located in Morinville, Alberta.

- Over 20,000 sq foot indoor space

- Modules over 200′

- 4 OH Cranes

- 50 tons total

- 23′ to hook

- 120′ craneway outside

- 30′ x 30′ shipping doors

- 7,500 sq foot indoor space

- 2 OH Cranes

- 10 tons total

- PCD1100 Beam Line

- FBD2500 Plate Processing System

- 125 ton Iron Worker

- 2 Hyd-Mech band saws

- Cantek radial arm drill

- 40″ band saw

- Coping machine

Recent Reviews

“Large company production and quality with Small company adaptability and flexibility”